Sheet Metal Fabrication

Sheet metal fabrication stands as a versatile manufacturing solution catering to the production of steel, stainless steel, aluminium and plastic parts, whether in small batches or large-scale quantities. At meviy, we specialize in delivering professional sheet metal fabrication services without imposing any minimum order requirements. Our on time delivery ensures that you have the flexibility to procure the necessary parts precisely when you need them.

Get Your First Part for FreeOrder Sheet Metal Fabrication Parts with meviy

Our Range of Materials for Sheet Metal Fabrication

Our service for sheet metal fabrication delivers exceptional quality at every stage, from material selection to finishing options. We offer a comprehensive range of materials, including stainless steel, aluminum, and galvanized steel, ensuring flexibility for diverse applications. With precise processes like laser cutting, bending, and welding, we guarantee reliable and consistent results for every project.

Customise your sheet metal for fabrication with options such as powder coating, galvanizing, or brushing to achieve the perfect balance of functionality and appearance. Our expertise in sheet metal fabrication ensures your parts meet the highest standards of precision, strength, and durability, making them ideal for a wide array of industries and applications.

- EN 1.0330 equiv.

- EN 1.0320 equiv. (hot coiled)

- EN 1.0330 equiv. (electrolytic zinc plating)

- EN 1.0330 equiv. (galvanized)

- EN 1.0330 equiv. (for SHIM)

- EN 1.0038 equiv

- EN 1.4301 equiv.

- EN 1.4016 equiv. (2B)

- EN 1.4301 equiv. (for SHIM)

- EN 1.4301 equiv. BA (Perforated)

- EN AW-5052 equiv.

- PET

- Acryl

- PC (polycarbonate)

- PVC (polyvinyl chloride)

- Powder Coating

- Electroless Nickel Plating

- Black Oxide

- Trivalent Chromate (clear)

- Trivalent Chromate (black)

- Electrolytic Zinc Plating

- Galvanised

- Hairline Finish

- Anodised (clear)

- Anodised (black)

- Black anodised (matt)

You can find further information on our range of materials and surface treatments in our specifications.

Sheet Metal Fabrication Services

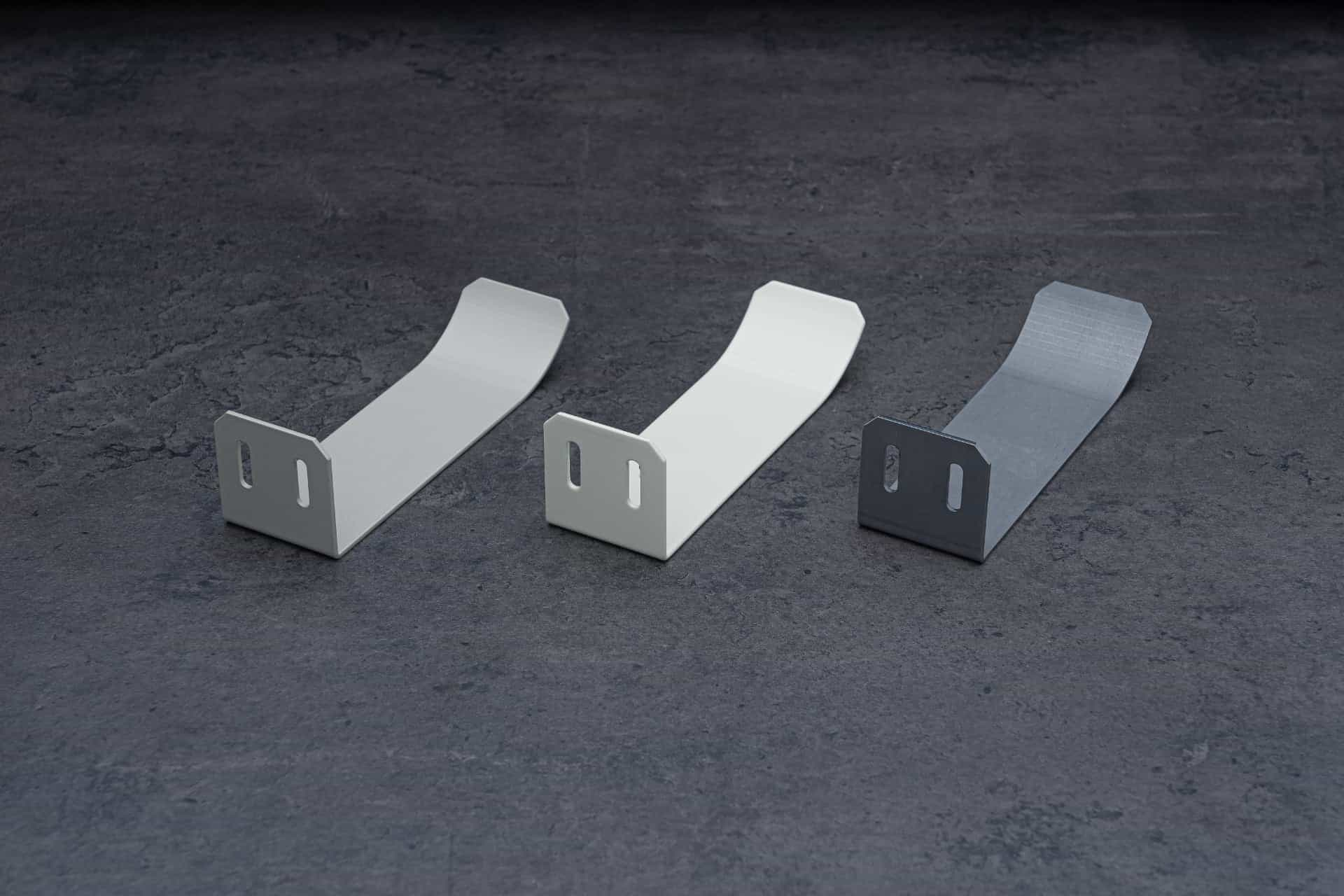

High-Quality Sheet Metal Fabrication with Powder Coated Finishes by meviy

Welcome to our slideshow of expertly crafted sheet metal fabrication parts! Produced with advanced manufacturing techniques, these components offer outstanding quality and performance for a wide range of applications.

Explore the versatility of our sheet metal for fabrication, available in various materials and finishes. Designed for precision and durability, they’re the ideal solution for projects requiring exceptional reliability and functionality. Trust our expertise in sheet metal fabrication to bring your designs to life with unmatched accuracy.

Sheet Metal Fabrication - Frequently Asked Questions (FAQ)

1. What is sheet metal fabrication?

Sheet metal fabrication is the process of shaping metal sheets into specific designs using techniques such as cutting, bending, and welding. This method is essential in creating components for industries like automotive, aerospace, and construction, making it a versatile choice for producing sheet metal for fabrication projects.

2. What materials can be used in sheet metal fabrication?

Materials commonly used in sheet metal fabrication include stainless steel, aluminum, copper, and galvanized steel. These options make sheet metal for fabrication adaptable to various needs, such as durability, corrosion resistance, or aesthetic appeal.

3. How precise is sheet metal fabrication?

Sheet metal fabrication is highly precise, especially when using advanced tools like CNC machines and laser cutters. These technologies ensure that sheet metal for fabrication meets exact specifications with tight tolerances and consistent quality.

4. What industries benefit from sheet metal fabrication?

Many industries utilize sheet metal fabrication, including automotive, aerospace, electronics, and medical devices. These sectors rely on the adaptability of sheet metal for fabrication to produce durable and functional components.

5. What surface finishes are available for fabricated sheet metal parts?

Options for finishing in sheet metal fabrication include powder coating, galvanising, anodising, and polishing. These finishes enhance the performance and appearance of sheet metal for fabrication, protecting it from corrosion and wear.

6. How can I customise my sheet metal fabrication project?

Customisation in sheet metal fabrication is achieved through tailored designs, materials, and finishes. By providing specifications for your sheet metal for fabrication, you can ensure the final product aligns perfectly with your project requirements.